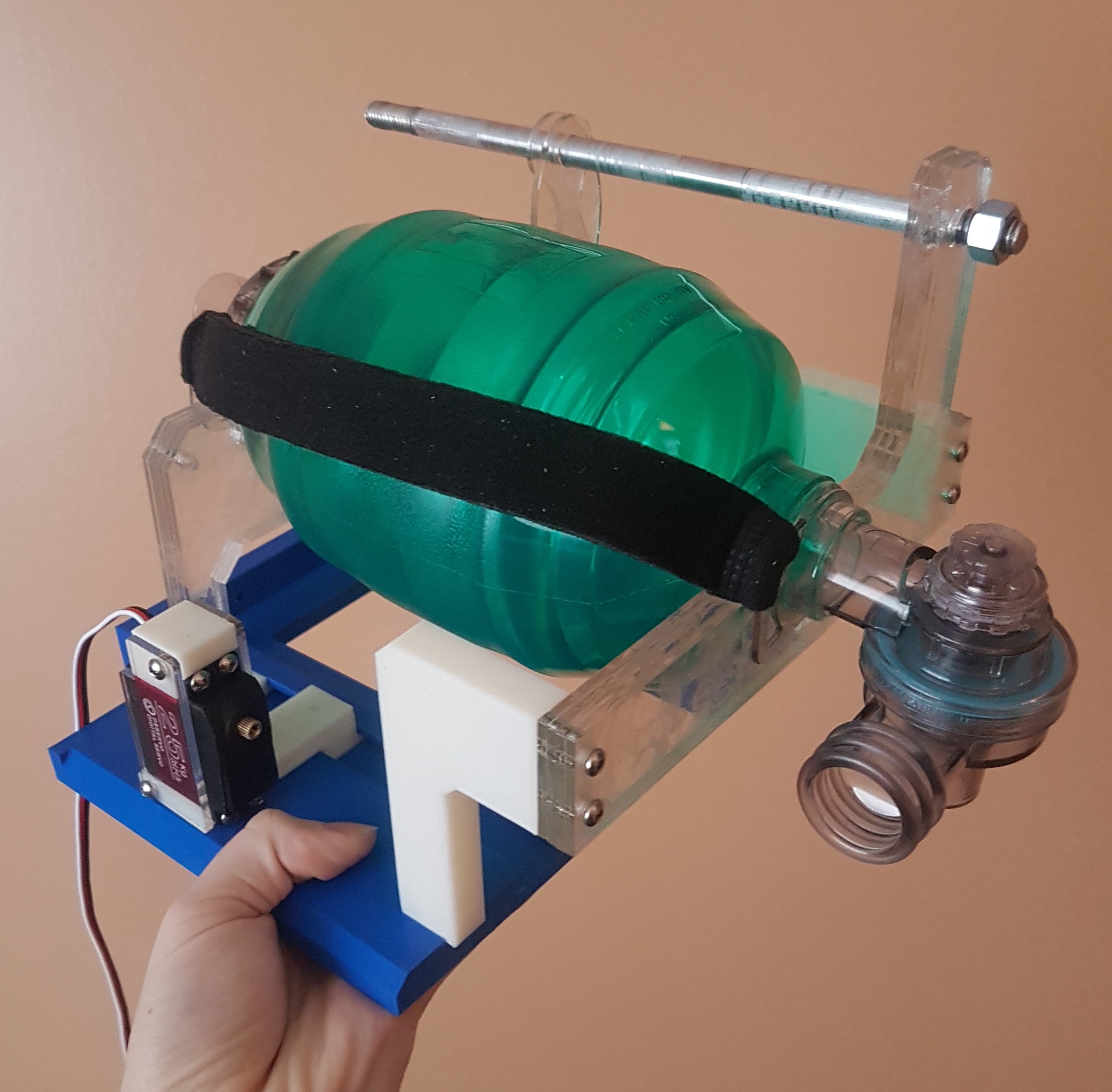

After a lot of 3D printing and laser cutting, we have fabricated most of the essential components of the design for testing the compression mechanism at Conestoga.

An interesting change we’ve made to the design while fabricating is to laser cut custom arms that will be pulled shut around the bag with the servo motor. This is not shown in the picture below, as the arms are set to be cut tomorrow morning before the trip to Conestoga. These arms are to replace the strap, since we can customize the shape to optimally squeeze the bag further than the strap would have been able to.

Note that the electronics housing is not yet fabricated, as this is not necessary for the upcoming tests.

To this date, this is the closest our design has come to the one designed in CAD.