The focus this week is manufacturing as much of the final design as possible. We will be returning to Conestoga College on Thursday for a second visit at the respiratory therapy lab.

The main structure of the design is comprised entirely of 3D printed and laser cut components. At the University, there is a collection of 3D printers, as well as a laser cutter available to use.

Some of the larger components will require significant print times, and may need to be printed overnight depending on printer availability. The goal is to fabricate the essential components first, to allow testing later in the week. The results of this testing will be used to update the design and re-manufacture components as required.

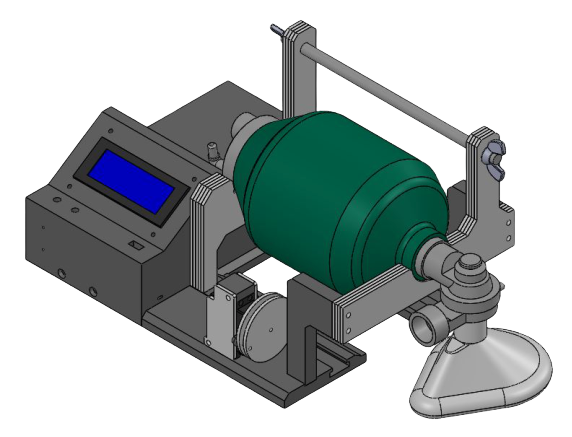

The current CAD model for the design is shown below. Note that the straps which will be squeezing the bag are not shown (for clarity), but they will be supported at one end by the tensioner rod and pulled at the other by the servo spool